Nanofabrication / nanomanufacturing

Nanofabrication is the essential bridge between the discoveries of the nanosciences and real-world nanotechnology products.

Partly based on: NanoFabNet, 2021, NanoFabNet, 2021a, https://nanofabnet.eu/ and https://susnanofab.eu/

© 2021-2022 by NanoFabNet and SUSNANOFAB

Table of contents

Nanofabrication has the potential to address major socio-economic challenges, from better and affordable health care to cleaner energy and transports, improved consumer goods and higher living standards. It encompasses many processes from the design, manipulation and control of matter at the nanoscale to the manufacture of nanoscale materials, nanostructures, components, devices and complex systems that exploit the unique physical and chemical phenomena that occur at these smaller scales, such as quantum and surface effects. The dimensional scale for nanofabrication is typically 1 to 100 nm. It is usually at this sub-micron scale that unusual or improved material behaviour is observed, which can be exploited for production of multifunctional devices with unique properties for a vast range of applications, thus having a profound impact on a multitude of industrial sectors. The vast potential of nanofabrication is undeniable, and it must be optimized.

This page is meant to link nanofabrication/nanomanufacturing to the other areas covered by the Handbook but not to be an exhaustive knowledge resource of this area. The latter is not needed since there are specialised platforms designed to bring experts together to foster knowledge exchange.

NanoFabNet Hub  The NanoFabNet Hub is the virtual platform for the NanoFabNet network, serving as an important tool for nanotechnology professionals and entities. The NanoFabNet Hub stands for (i) a well-implemented, guided approach to high levels of safety and sustainability, (ii) trusted technical reliability and quality, and (iii) compliance with and drive of harmonisation, standardisation, and regulation requirements, amongst all of its members and along their nanofabrication value chains.

The NanoFabNet Hub is the virtual platform for the NanoFabNet network, serving as an important tool for nanotechnology professionals and entities. The NanoFabNet Hub stands for (i) a well-implemented, guided approach to high levels of safety and sustainability, (ii) trusted technical reliability and quality, and (iii) compliance with and drive of harmonisation, standardisation, and regulation requirements, amongst all of its members and along their nanofabrication value chains.

SUSNANOFAB digital platform  The Open Access Digital Platform interoperates with current platforms, projects and other initiatives at the European level. The main services and activities provided by the Digital Platform are (i) EU database with access to multiple networks, (ii) cooperation on standarisation activities, (iii) promotion of best practices, and (iv) brokerage, training and support services.

The Open Access Digital Platform interoperates with current platforms, projects and other initiatives at the European level. The main services and activities provided by the Digital Platform are (i) EU database with access to multiple networks, (ii) cooperation on standarisation activities, (iii) promotion of best practices, and (iv) brokerage, training and support services.

Sustainable nanofabrication

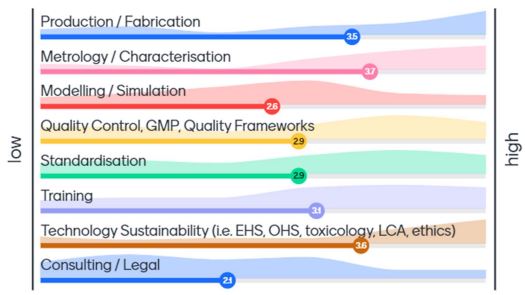

As nanofabrication and sustainability are quite young fields, the cross-over between them is even more recent. By searching both combined terms with an online search engine, the first results found are for European projects such as SusNanoFab and NanoFabNet showing that this subject is particularly on the rise. The main issues of sustainable nanofabrication were highlighted by the stakeholders during the 1st NanoFabNet Development Workshop (DW), by ranking categories on their importance on this subject. The categories considered to be of high importance are:

As nanofabrication and sustainability are quite young fields, the cross-over between them is even more recent. By searching both combined terms with an online search engine, the first results found are for European projects such as SusNanoFab and NanoFabNet showing that this subject is particularly on the rise. The main issues of sustainable nanofabrication were highlighted by the stakeholders during the 1st NanoFabNet Development Workshop (DW), by ranking categories on their importance on this subject. The categories considered to be of high importance are:

- metrology/characterisation in association with the production processes

- sustainability, training and standardisation

Mapping the scientific landscapes of nanofabrication & sustainability NanoFabNet report delineating the boundaries of the scientific fields of ‘nanofabrication’ and ‘sustainability’ in search of overlaps in both research and innovation (R&I) topics and individual experts that specialise in their pursuit.

Common Challenges & Opportunities in sustainable Nanofabrication identified by NanoFabNet A state of the art is proposed to present the different issues involved in sustainable nanofabrication (standardisation, life cycle sustainability and risk assessment, education/skills and infrastructures).

This guided the development of strategic plans in the two project mentioned.

NanoFabNet’s EU 2030 strategic plan for nanofabrication  02/08/2022

02/08/2022

The NanoFabNet published its ultimate roadmap to establish and secure the ongoing advancement and innovation in sustainable micro- and nanofabrication. The roadmap assigns a number of important activities to the newly formed NanoFabNet Hub (see above). SUSNANOFAB is still revising its roadmap, which will be added here when finalised.

Terminology in nanofabrication

The international standard ISO/TS 80004-8 (Nanotechnologies -Vocabulary - Part 8: Nanomanufacturing processes) makes an inventory of the different processes, which demonstrates the great diversity of existing approaches, each with their own specificities. The ISO/TS 80004-8 differentiates also between the terms “nanofabrication” and “nanomanufacturing” by arguing that nanomanufacturing encompasses a broader range of processes than does nanofabrication, as it takes into account all nanofabrication techniques, as well as techniques associated with materials processing and chemical synthesis. In the following, however, the terms nanofabrication and nanomanufacturing will be used interchangeably.

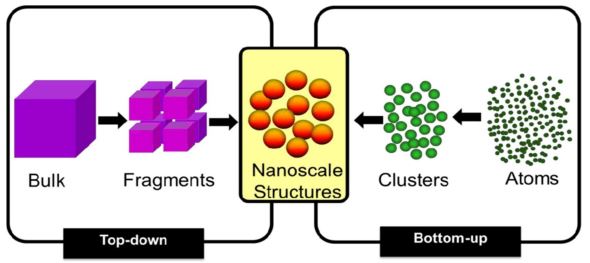

Figure 1. Representation of the nanofabrication approaches: “top-down” versus “bottom-up” (Rawat, 2015).

Figure 1. Representation of the nanofabrication approaches: “top-down” versus “bottom-up” (Rawat, 2015).

To produce nanoscale structures via nanofabrication approaches, two main routes can be taken (see Figure 1). A “top-down” approach, which starts from micro-systems and miniaturises them to a nanoscale (as a carver would go from a block of stone to its final sculpture), whereas a “bottom-up” approach starts from atoms or molecular blocks to build nano-scale structures (as a mason would build a wall). The bottom-up approach is, for the moment, less common but allows more control over the nanoparticles production.

Additionally to these clear definitions of what the field is about, further harmonisation and achieving interoperability also with neighbouring fields like nanosafety and nanoinformatics has to be supported by a taxonomy, which could then be further developed into an ontology or integrated into existing ones.

Nanofabrication Competence Map: Infrastructures, Knowledge & Skills - Proposal for a new Nanofabrication Taxonomy A completely new concept of generic instrument names together with categorisation based on the existing ISO standard is proposed. This ISO standard needed to be heavily modified and extended in order to cover all needs of current academic cleanroom nanofabrication centres.

Implementation roadmap for infrastructures, knowledge & skills development in nanofabrication Building on the NanoFabNet report ‘Nanofabrication Competence Map: Infrastructures, Knowledge & Skills – Proposal for a new Nanofabrication Taxonomy‘, this NanoFabNet report provides a roadmap for the implementation of the proposed taxonomy, in order to support infrastructures, knowledge and skills developments within the wider nanofabrication community.

Training

Additional trainings: SUSNANOFAB webinars

Standardisation

Challenges & Opportunities of Validating, Harmonising & Standardising industrial-scale Nanofabrication Based on an in-depth desk analysis of scientific literature and the collection of key stakeholders’ opinions, a detailed analysis of the challenges & opportunities posed by any validation, harmonisation and standardisation efforts in sustainable nanofabrication has been carried out.

References

- NanoFabNet, 2021: ‘NanoFabNet. Common Challenges & Opportunities in sustainable Nanofabrication. Report 2021. https://acumenist.com/wp-content/uploads/simple-file-list/AcumenIST-Press/20210803_NanoFabNet_Report_Common-Challenges-of-sustainable-Nanofabrication.pdf.

- NanoFabNet, 2021a: ‘NanoFabNet. Challenges & Opportunities of Validating, Harmonising & Standardising industrial-scale Nanofabrication. Report 2021. https://acumenist.com/wp-content/uploads/simple-file-list/AcumenIST-Press/20210701_NanoFabNet_Report_Challenges-and-Opportunities-of-Validating-Nanofabrication.pdf.

- Rawat, 2015: Rawat, R.S. Dense Plasma Focus – From Alternative Fusion Source to Versatile High Energy Density Plasma Source for Plasma Nanotechnology. J. Phys.: Conf. Ser. 2015, 591, 012021. https://iopscience.iop.org/article/10.1088/1742-6596/591/1/012021.